Spiral Dryer Screen Introduction

In today’s fast-paced industrial landscape, efficiency and durability are critical in every aspect of production, especially in drying processes. The spiral dryer screen is an innovation that stands out in the industry, providing a reliable and effective solution for moisture removal across various applications. This article delves into the unique advantages of spiral dryer screens, exploring why they are a superior choice in industrial drying systems.

What is a Spiral Dryer Screen?

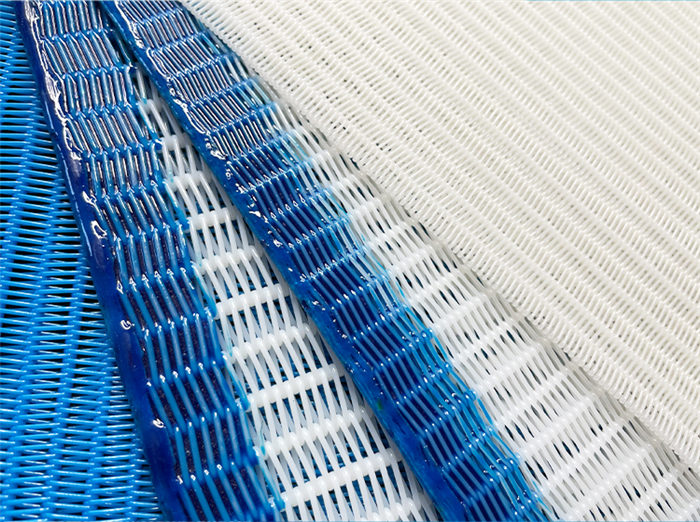

A spiral dryer screen is a specialized type of fabric used in the drying sections of industrial processes, particularly in industries like paper manufacturing, textiles, and food processing. These screens are constructed using high-quality polyester or other synthetic materials, designed in a spiral structure that enhances their performance.

The spiral design is not just for aesthetics; it plays a crucial role in the screen’s functionality. The spiral formation allows for optimal air and water flow, which is essential in achieving efficient drying. This structure also contributes to the screen’s strength and durability, making it a long-lasting component in industrial applications.

Key Advantages of Spiral Dryer Screen

1. Efficiency in Moisture Removal

One of the most significant advantages of spiral dryer screens is their efficiency in removing moisture from materials. The open structure of the spiral design facilitates better air circulation and water drainage, which accelerates the drying process. This efficiency is particularly beneficial in industries where time is of the essence, such as in paper manufacturing, where rapid drying is crucial to maintaining production speed.

2. Durability and Longevity

Spiral dryer screens are built to last. The materials used in their construction, typically high-grade polyester, are resistant to wear and tear, even in the harshest industrial environments. This durability means that the screens require less frequent replacement, reducing downtime and maintenance costs. Their robust design ensures they can withstand the mechanical stress and high temperatures common in industrial drying processes.

3. Customizability

Every industrial process has its unique requirements, and the spiral dryer screen can be customized to meet these specific needs. Manufacturers offer variations in pore sizes, thickness, and tensile strength, allowing businesses to select the exact specifications that best suit their operations. This customizability ensures optimal performance, regardless of the application.

4. Energy Savings

The efficiency of spiral dryer screens translates directly into energy savings. Because these screens enhance the drying process, less energy is required to achieve the desired moisture levels. This reduction in energy consumption not only lowers operational costs but also contributes to a more sustainable production process, aligning with the growing emphasis on eco-friendly industrial practices.

5. Easy Maintenance

Maintaining industrial equipment can be time-consuming and costly. However, spiral dryer screens are designed with ease of maintenance in mind. Their construction allows for quick cleaning and simple repairs, minimizing downtime and ensuring that the production process remains as smooth and uninterrupted as possible. This ease of maintenance further adds to the overall cost-effectiveness of these screens.

Applications of Spiral Dryer Screen

Spiral dryer screens are versatile and can be used in a wide range of industries.

- Paper Manufacturing: In the paper industry, these screens are essential in the drying sections of paper machines. They help remove water from the paper web, ensuring a smooth and efficient drying process, which is critical to maintaining the quality and consistency of the final product.

- Textiles: In textile production, spiral dryer screens are used in processes where moisture needs to be removed from fabrics. The screens’ efficient moisture removal capabilities ensure that textiles are dried quickly and uniformly, preventing issues like shrinkage or uneven drying.

- Food Processing: In the food industry, maintaining hygiene and efficiency is paramount. Spiral dryer screens are used in drying various food products, where their easy-to-clean structure and efficient drying capabilities help maintain product quality and safety.

Why Choose Spiral Dryer Screens Over Other Drying Solutions?

When compared to other drying screens or fabrics, spiral dryer screens offer superior performance and cost-effectiveness. Traditional flat dryer screens or woven fabrics may lack the open structure and durability that spiral dryer screens provide. Additionally, the customizability and ease of maintenance of spiral dryer screens make them a more adaptable and practical choice for a variety of industrial applications.

Industries that have switched to spiral dryer screens often report significant improvements in drying efficiency, reduced energy costs, and longer intervals between replacements. These benefits, combined with the robust and customizable nature of the screens, make them a wise investment for any business looking to optimize its drying processes.

Conclusion

Spiral dryer screens represent the pinnacle of innovation in industrial drying solutions. Their unique spiral design, combined with high-quality materials, provides unparalleled efficiency, durability, and energy savings. Whether in paper manufacturing, textiles, or food processing, these screens offer a reliable and cost-effective solution that can be tailored to meet the specific needs of any application.

For industries looking to enhance their drying processes, spiral dryer screens are the clear choice. Investing in these advanced screens not only improves production efficiency but also contributes to long-term savings and sustainability. Explore the potential of spiral dryer screens and elevate your industrial drying processes to new heights.