Introduction

In the paper manufacturing industry, the efficiency of the drying process is critical to the overall quality and productivity of paper production. Spiral fabric, specifically designed for paper machines, plays a crucial role in this process. This article explores the unique benefits of spiral fabric for paper machines, highlighting why it is an indispensable component in modern papermaking.

What is Spiral Fabric for Paper Machines?

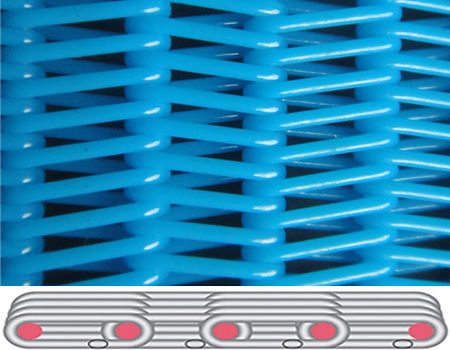

Spiral fabric is a specialized type of dryer fabric used in the drying section of paper machines. It is constructed from durable synthetic materials, often polyester, and is woven into a spiral structure. This design not only enhances the fabric’s mechanical properties but also optimizes its performance in the high-stress environment of paper production.

The spiral structure of the fabric provides superior air permeability and facilitates efficient moisture removal, which are essential in the drying process. Additionally, the fabric’s resilience and adaptability make it suitable for various paper grades and production speeds, ensuring consistent results across different applications.

Key Advantages of Spiral Fabric for Paper Machines

1. Enhanced Drying Efficiency

One of the primary advantages of using spiral fabric in paper machines is its ability to enhance the drying process. The spiral design allows for better air circulation and water drainage, leading to faster and more uniform drying of the paper web. This efficiency is particularly beneficial in high-speed paper production, where maintaining the quality and consistency of the paper is crucial.

2. Superior Durability and Longevity

Spiral fabric is designed to withstand the rigorous conditions of paper machine operations. The materials used, typically high-quality polyester, are resistant to wear, tear, and abrasion, ensuring that the fabric lasts longer even under continuous operation. This durability translates to reduced downtime and lower maintenance costs, as the fabric does not need to be replaced as frequently as other types of dryer fabrics.

3. Consistent Paper Quality

The uniform drying provided by spiral fabric helps maintain the consistency of the paper’s moisture content, which is essential for producing high-quality paper. Uneven drying can lead to defects such as curling, wrinkles, or variations in thickness, which can compromise the final product. Spiral fabric ensures that the paper is dried evenly across the entire web, reducing the risk of these issues and improving the overall quality of the paper.

4. Customization for Specific Applications

Spiral fabric can be customized to meet the specific needs of different paper grades and machine configurations. Whether it’s adjusting the permeability, thickness, or tensile strength, manufacturers can tailor the fabric to match the exact requirements of the production process. This level of customization ensures optimal performance and helps manufacturers achieve their desired outcomes more effectively.

5. Energy Efficiency

The efficient moisture removal capability of spiral fabric contributes to significant energy savings in paper production. By speeding up the drying process, the fabric reduces the energy required to achieve the desired moisture levels in the paper. This not only lowers operational costs but also supports environmental sustainability by reducing the overall energy consumption of the production facility.

6. Easy Installation and Maintenance

Spiral fabric is designed for easy installation and maintenance, making it a practical choice for paper mills. Its structure allows for quick and straightforward installation on paper machines, minimizing downtime during fabric changes. Additionally, the fabric’s resistance to contaminants and ease of cleaning reduce the need for frequent maintenance, further enhancing its cost-effectiveness.

Applications of Spiral Fabric in Paper Machines

Spiral fabric is used in various sections of paper machines, particularly in the drying process. It is suitable for a wide range of paper grades, including:

- Printing and Writing Papers: The uniform drying provided by spiral fabric ensures that these papers maintain a smooth surface and consistent thickness, which are essential for high-quality printing and writing.

- Packaging Papers: For packaging materials, which require strength and durability, spiral fabric ensures that the paper is dried to the correct moisture content, preventing issues like warping or cracking.

- Tissue Papers: In the production of tissue papers, where softness and absorbency are key, spiral fabric helps achieve the delicate balance between thorough drying and preserving the paper’s softness.

- Specialty Papers: Spiral fabric is also used in the production of specialty papers, where precise control over the drying process is required to achieve specific characteristics or finishes.

Why Choose Spiral Fabric Over Other Dryer Fabrics?

When compared to other types of dryer fabrics, spiral fabric offers several distinct advantages. Traditional flat dryer fabrics may not provide the same level of air permeability or durability, leading to less efficient drying and more frequent replacements. Woven fabrics, while effective in some applications, often lack the customization options and resilience that spiral fabric provides.

Spiral fabric’s ability to enhance drying efficiency, reduce energy consumption, and maintain consistent paper quality makes it a superior choice for paper mills. Its durability and ease of maintenance further contribute to its cost-effectiveness, making it an investment that pays off in the long run.

Conclusion

Spiral fabric for paper machines is a critical component in modern paper production, offering unmatched benefits in terms of efficiency, durability, and quality. Its unique spiral design, combined with the strength of synthetic materials, ensures that paper is dried quickly, evenly, and with minimal energy consumption. Whether producing printing papers, packaging materials, or specialty products, spiral fabric provides the reliability and performance needed to achieve high-quality results.

For paper manufacturers looking to optimize their drying processes and improve product quality, spiral fabric is the clear choice. By investing in this advanced fabric, paper mills can enhance their production capabilities, reduce operational costs, and maintain a competitive edge in the market. Explore the potential of spiral fabric for your paper machines and experience the benefits firsthand.