Polyester Spiral Mesh Belts for Dewatering, Drying, Forming

Description Spiral mesh dryer belts have a specially designed spiral structure. The spiral meshes are produced from flat ribbon spirals, which are connected to a straight round rod. Due to the special structure of the Polyester Spiral mesh belt with continuous and sea……

Description

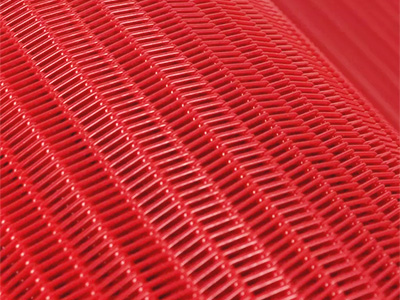

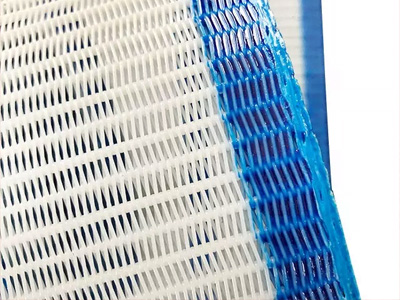

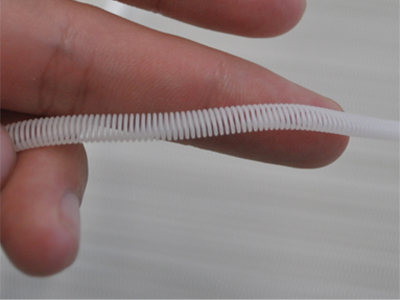

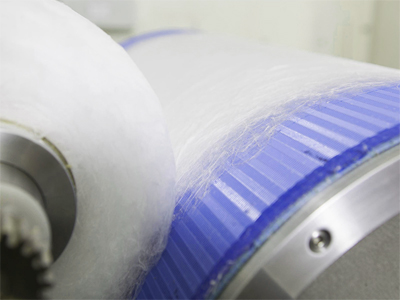

Spiral mesh dryer belts have a specially designed spiral structure. The spiral meshes are produced from flat ribbon spirals, which are connected to a straight round rod. Due to the special structure of the Polyester Spiral mesh belt with continuous and seamless screen spiral, it is very suitable for applications with high mechanical load and unmeet the seam.

Do not have a seam |

Glued edge |

Each Spiral mesh belt will be heat-setting before leaving the factory. Spiral meshes are available in polyester and PPS. The maximum heat-setting temperature of the Polyester Spiral mesh belt is 200 °C, and it can be used for a long time at 150 °C. The Spiral mesh belt made of PPS has a maximum temperature of 290°C for heat setting and can be used for a long time at 240°C.

The heat setting treatment ensures the structural stability of the Spiral mesh belt, improves the surface flatness, improves the physical and mechanical properties of the fiber, and greatly enhances the service life of the mesh belt.

Polyester monofilament spiral loop |

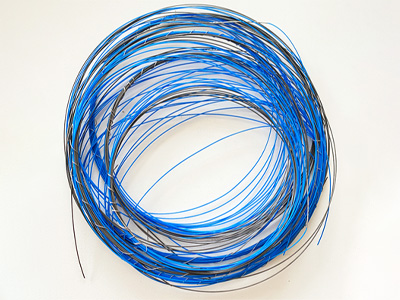

Threading for connection |

Feature

MACROKUN SCREEN’s Polyester Spiral Mesh Belts Properties:

♦ Use hot air to set the shape, evenly heat, and improve the service life of the mesh belt.

♦ Selected raw yarn, smooth surface, not easy to stick, easy to clean.

♦ High-temperature resistance, polyester up to 150°C, PPS up to 240°C.

♦ Excellent chemical stability, BPA-free, Food grade certification.

♦ Seamless connection, no swelling at the joint, and the same air permeability in the whole filtering area.

♦ The width supports 10 cm to 10 meters, any length you need.

♦ Sealed edges for lasting, economical solutions.

♦ Easy to install, easy to repair.

Application

The subtle weaving of the spiral Mesh dryer belt allows transporting the product over ventilated surfaces without product abrasion. Ideal in filter belts, dryer belts or conveyor belts in product washing, or for industry drying, nonwoven forming, and thermal applications including drying of veneers, manufacture of gypsum plasterboard or for multi-stage dryers in foodstuff processing, etc.

♦ Food processing industry

♦ Pasta sector, for drying and pasteurization

♦ Ready-to-use produce sector, for washing vegetables

♦ Food processing industry, for drying of fruits

♦ Dairy industry, for filtration processes

♦ Fishing industry, for transportation

|

|

Specifications

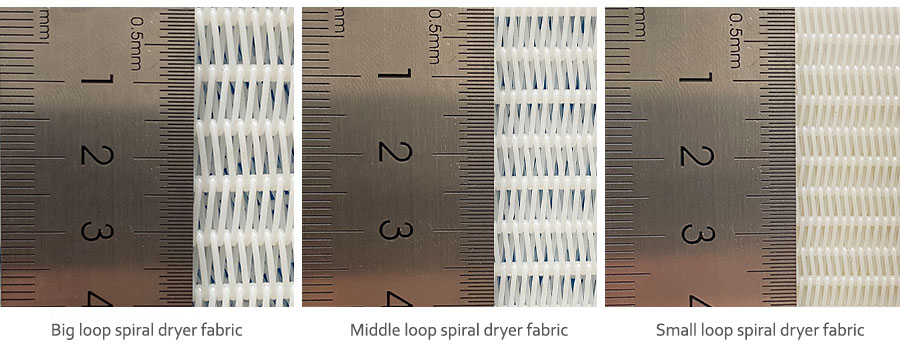

We can offer a wide range of options to suit your application to achieve your optimum air permeability, filtration efficiency, throughput and tracking stability. Items to choose from include: various types of yarn diameters from 0.5mm to 1.2mm; small, medium and large spiral loops; flat or round yarn; and yarn material.

| Type | Spiral loop width (mm) |

Filament diameter (mm) |

Strength (N/cm) |

Weight (Kg/m2) |

Thickness (mm) |

Air permeability (m3/m2h) |

CFM (127/pa) |

||

| Spiral ring monofilament | Connection Wire | filler material monofilament | |||||||

| Small loop 5080A1 | 5.2 | 0.5 | 0.8 | 0.60*3 | 1800 | 1.5 | 2.1 | 4480 | 280 |

| Medium loop 6890A1 | 8 | 0.68 | 0.9 | 0.80*4 | 2000 | 2 | 2.45 | 6080 | 380 |

| Medium loop 6890B1 | 7.15 | 0.68 | 0.9 | 0.90*3 | 2000 | 1.9 | 2.45 | 5760 | 360 |

| Medium loop 6890B2 | 7.15 | 0.68 | 0.9 | 0.80*3 | 2000 | 1.85 | 2.45 | 7750 | 484 |

| Medium loop 6890B3 | 7.15 | 0.68 | 0.9 | Flat Wire 2.1*0.80 | 2000 | 1.8 | 2.45 | 9000 | 563 |

| Medium loop 6890B4 | 7.15 | 0.68 | 0.9 | Flat Wire 2.1*0.88 | 2000 | 1.85 | 2.45 | 8000 | 500 |

| Medium loop 6890B5 | 7.15 | 0.68 | 0.9 | Conductive carbon wire | 2000 | 1.6 | 2.45 | 10000 | 625 |

| Large loop 9090A1 | 8 | 0.9 | 0.9 | 0.90*3 | 2300 | 2.3 | 3.03 | 7500 | 468 |

| Large loop 90110A1 | 10 | 0.9 | 1.1 | 1.0*4 | 2000 | 2.4 | 3.15 | 6240 | 390 |

| Alkali resistance PA90110A2 | 10 | 0.9 | 1.1 | 1.2*3 | 2000 | 2.25 | 3.15 | 6240 | 390 |

| Large loop 10090A1 | 8 | 1 | 0.9 | 1.0*3 | 2000 | 2.5 | 3.6 | 5000 | 315 |

| Large loop 120130A1 | 1.2 | 1.2 | 1.3 | 1.2*3 | 2600 | 2.85 | 4.3 | 7500 | 468 |