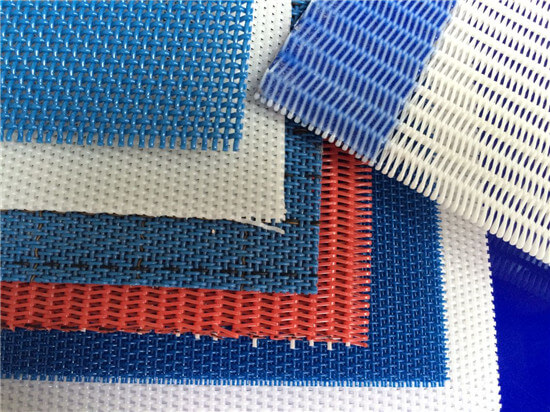

Purchasing polyester mesh belts for wetlaid nonwoven production at wholesale prices offers significant advantages for manufacturers. Not only does it allow for cost savings, but it also ensures a consistent supply of high-quality belts that are essential for maintaining efficient production processes. This article explores the benefits of buying polyester mesh belts wholesale, factors to consider when selecting a supplier, and how to maximize the value of your wholesale purchase.

The Benefits of Wholesale Purchasing

- Cost Savings One of the most significant advantages of buying polyester mesh belts at wholesale prices is the potential for cost savings. Wholesale prices are generally lower than retail, allowing manufacturers to reduce the per-unit cost of the belts. This reduction can be especially beneficial for large-scale operations that require a continuous supply of mesh belts.

- Consistent Supply Purchasing in bulk ensures that you have a consistent supply of polyester mesh belts on hand, reducing the risk of production delays due to stock shortages. Having an ample supply readily available allows your production process to run smoothly without interruptions.

- Streamlined Procurement Buying wholesale simplifies the procurement process by reducing the need for frequent reorders. By purchasing larger quantities at once, you can streamline inventory management and focus on other critical aspects of your production operation.

- Supplier Relationships Establishing a long-term relationship with a supplier through wholesale purchasing can lead to additional benefits such as priority service, better payment terms, and access to the latest product innovations. Suppliers are often more willing to offer discounts and incentives to customers who make significant purchases regularly.

Key Considerations When Buying Wholesale

- Quality Assurance When purchasing polyester mesh belts wholesale, it is essential to ensure that the quality of the belts meets your production standards. Even with cost savings, compromising on quality can lead to higher long-term costs due to increased maintenance, downtime, and lower product quality. Always verify the quality of the belts through samples or certifications before committing to a bulk purchase.

- Customization Options Depending on your production needs, you may require polyester mesh belts with specific dimensions, mesh sizes, or material properties. When buying wholesale, check if the supplier offers customization options to ensure the belts are tailored to your exact requirements. Customization might come at an additional cost, but it ensures that the belts perform optimally in your production environment.

- Supplier Reliability The reliability of your supplier is crucial when purchasing wholesale. Choose a supplier with a proven track record of delivering high-quality products on time. Reliable suppliers will also provide consistent quality across batches, reducing the risk of variations that could affect your production process.

- Bulk Discounts Inquire about bulk discounts when negotiating with suppliers. Many suppliers offer tiered pricing based on the quantity purchased, so the larger your order, the more significant the discount. Understanding the pricing structure can help you maximize your savings while ensuring that you get the best possible deal.

- Shipping and Logistics Consider the logistics involved in purchasing polyester mesh belts wholesale, including shipping costs and delivery times. Efficient logistics are essential to ensure that your bulk orders arrive on time and in good condition. Some suppliers may offer free or discounted shipping for large orders, which can further enhance the value of your purchase.

Maximizing the Value of Wholesale Purchases

- Inventory Management Effective inventory management is key to maximizing the value of your wholesale purchase. Ensure that your storage facilities are capable of handling large quantities of polyester mesh belts without compromising their quality. Proper storage conditions, such as temperature and humidity control, will prevent degradation and extend the shelf life of the belts.

- Forecasting and Planning Accurate forecasting and production planning are essential when buying wholesale. By predicting your production needs over a specific period, you can purchase the appropriate quantity of polyester mesh belts, avoiding overstocking or understocking. This approach minimizes waste and optimizes your investment.

- Negotiating Contracts When buying wholesale, consider negotiating a long-term contract with your supplier. A contract can lock in favorable pricing, ensure a steady supply, and provide additional benefits such as extended payment terms or exclusive access to new products. A well-negotiated contract can significantly enhance the value of your wholesale purchase.

- Leverage Supplier Expertise Suppliers often have in-depth knowledge of their products and can offer valuable insights into how to optimize the use of polyester mesh belts in your production process. By leveraging this expertise, you can improve efficiency, reduce waste, and enhance the overall performance of your wetlaid nonwoven production.

Conclusion

Purchasing polyester mesh belts for wetlaid nonwoven applications at wholesale prices offers numerous benefits, including cost savings, a consistent supply, and streamlined procurement processes. However, to maximize the value of your wholesale purchase, it’s crucial to consider factors such as quality assurance, supplier reliability, and customization options. Effective inventory management, accurate forecasting, and strategic negotiation can further enhance the benefits of buying wholesale. By carefully selecting your supplier and optimizing the procurement process, you can ensure that your investment in polyester mesh belts contributes to the long-term success and efficiency of your production operation.