Polyester Linear Screen Mesh Conveyor Belt

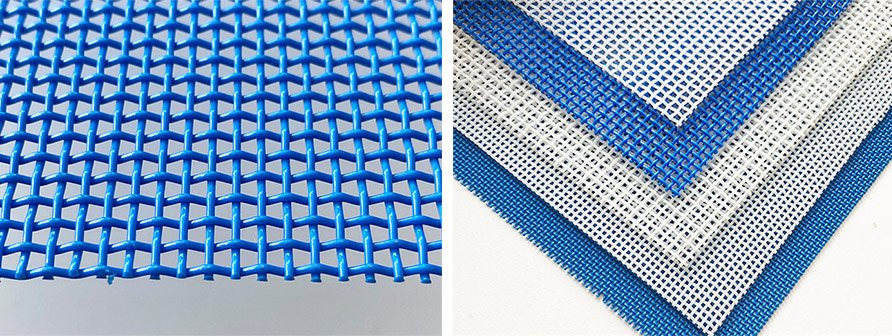

Description Polyester plain weave mesh fabrics are also called linear screen cloth, polyester mesh conveyor belts, and polyester monofilament process conveyor belting. The weaving pattern is 2-shed and 3-shed available in various meshes, caliper, GSM and air permeabil……

Description

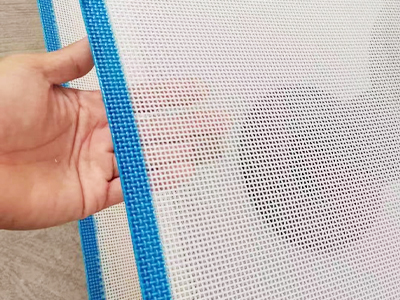

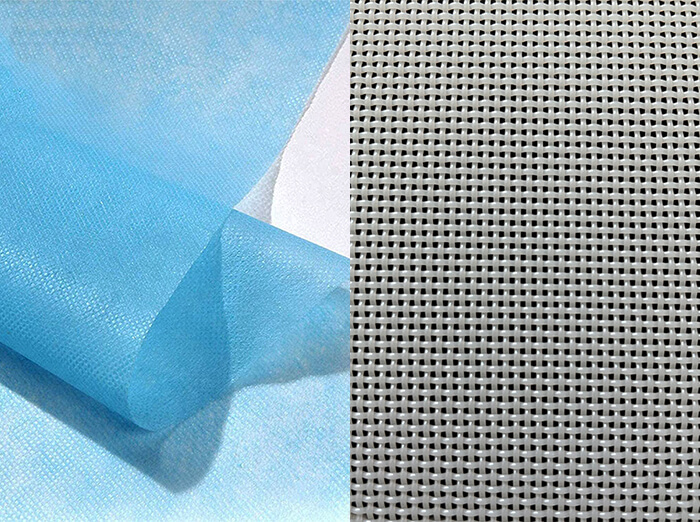

Polyester plain weave mesh fabrics are also called linear screen cloth, polyester mesh conveyor belts, and polyester monofilament process conveyor belting.

The weaving pattern is 2-shed and 3-shed available in various meshes, caliper, GSM and air permeability for different applications. Polyester monofilament process conveyor belting is available in a wide variety of yarn thicknesses and apertures.

They are widely used in various industries as dryer fabrics, conveyor belts, filter cloths and food & vegetables drying mesh belts.

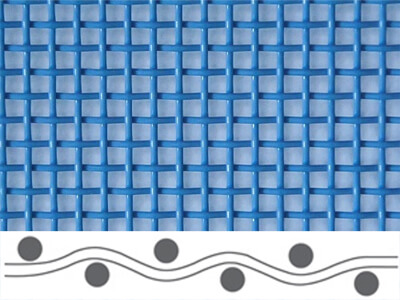

2-Shed Polyester Linear Screen

Filter fabrics with the 2-shed plain weave have high weave stability and predefined uniform size of apertures, so they can also be used to sort particles according to their size on linear screen separators.

Polyester Linear Screen for 2-Shed

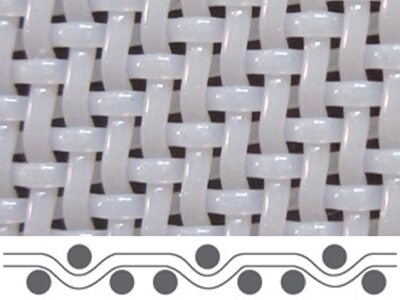

3-Shed Polyester Linear Screen

Filter fabrics with the three-shaft twill weave have a very high dewatering ability and a higher wear resistance than fabrics with the plain weave.

Polyester Linear Screen for 3-Shed

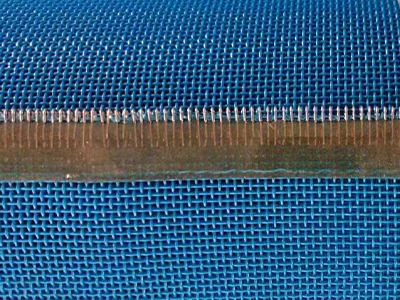

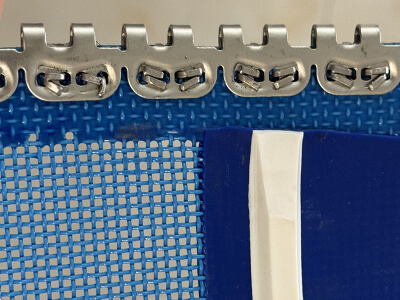

The jointing mechanism of the Polyester Mesh belts

The jointing mechanism of the polyester mesh conveyor belts is given special attention and can be manufactured in a number of ways ranging from metallic clipper types, and integrated spirals to seamless.

Clipper Type

Staple Fastener Clipper Type

Integrated Spirals

Seamless

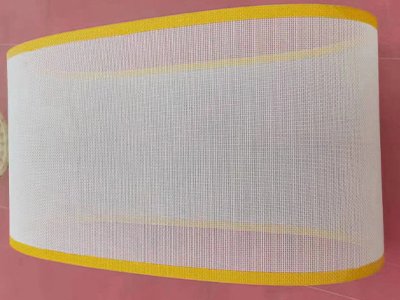

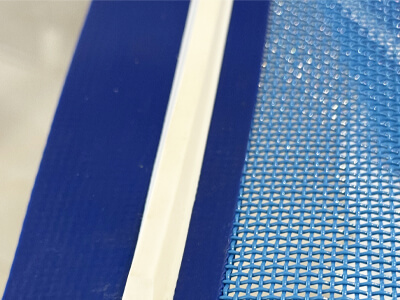

The edges of the Polyester Mesh belts

The edges of the polyester mesh conveyor belts too are given extra attention and can be reinforced with special materials that make them resistant to fraying and abrasion by impregnation, encapsulation, or welding.

Glue Sealed Edge

Sewn Edge

Tracking Guide Edge

PVC wrapping and V-guides Edge

Polyester mesh belt is mainly used for the following processes:

● filtration

● separation

● drain

● drying

● dewatering

Feature

● Linear screen cloth has an accurate open area and aperture is uniform

● The nature of Polyester mesh belt is such that it offers a very durable long-lasting media for extended life.

● Strong polyester fibers provide excellent stability and good wear resistance.

● All kinds of joints are suitable including endless joint

● Food approval: US FDA approval

● Working temperature: -75°C to +150°C

Application

● Pulp board making

● Wood industry: Dryer belts of woodchips, particle boards, MDF/HDF, etc

● Nonwoven cloth industry

● Food drying

● Material screening and separation

● Environment protection: sludge dewatering in belt press filters

● The pre-cleaning process before fruit and vegetable processing

● Glass fiber mat production line

Polyester Linear Screen Mesh Belts for Washing

Polyester Linear Screen Mesh Belts for Nonwoven

Specifications

| Model | Wire diameter

(mm) |

Density

(wire/centimeter) |

Strength (N/cm) |

weight

(kg/m2) |

Thickness (mm) |

Mesh Radial/latitude

(mm) |

Aperture Radial/latitude

(mm) |

permeability

(m3/m2/h) |

CFM/127Pa | open aven | |||

| warp | weft | warp | weft | surface | joint | ||||||||

| 021002 blue | 1 | 1 | 2.85 | 2.65 | 1600 | 650 | 0.6 | 1.85 | 7.10/6.73 | 2.50/2.77 | 32000 | 2000 | 52.55 |

| 031002 blue/white | 1 | 1 | 3.2 | 3.25 | 1600 | 650 | 0.8 | 1.86 | 8.10/8.20 | 2.12/2.07 | 25600 | 1600 | 45.9 |

| 03902 | 0.9 | 0.9 | 3.9 | 3.65 | 1600 | 650 | 0.55 | 1.7 | 9.60/9.30 | 1.66/1.83 | 20000 | 1250 | 46.58 |

| 04902 | 0.9 | 0.9 | 4.65 | 4.7 | 1600 | 650 | 0.95 | 1.66 | 44542 | 1.25/1.22 | 17600 | 1170 | 33.55 |

| 04602 | 0.5 | 0.6 | 4.4 | 5.2 | 1600 | 650 | 0.58 | 1.23 | 12/13.2 | 1.72/1.32 | 19000 | 1187 | 53.32 |

| 05602 | 0.6 | 0.6 | 5.9 | 5.6 | 1600 | 650 | 0.62 | 1.1 | 14.98/14.2 | 1.09/1.18 | 18000 | 1125 | 42.89 |

| 05802 | 0.8 | 0.8 | 5.1 | 5.3 | 1600 | 650 | 0.89 | 1.48 | 13/13.5 | 1.16/1.08 | 15840 | 990 | 34.09 |

| 06652 | 0.65 | 0.65 | 7.4 | 6.8 | 1600 | 650 | 0.65 | 1.19 | 18.8/17.3 | 0.70/0.82 | 14400 | 1190 | 28.96 |

| 06802 blue/white | 0.8 | 0.8 | 6.6 | 6.5 | 1600 | 650 | 0.85 | 1.45 | 16.8/16.5 | 0.72/0.73 | 11600 | 725 | 22.65 |

| 06702 blue/white | 0.7 | 0.7 | 7 | 7 | 1600 | 650 | 0.77 | 1.3 | 17.8/17.8 | 0.72/0.72 | 11000 | 690 | 26.01 |

| 07802 | 0.8 | 0.8 | 7.8 | 7 | 1600 | 650 | 1.1 | 1.45 | 20.3/18 | 0.32/0.54 | 5920 | 370 | 16.54 |

| 09502 | 0.5 | 0.5 | 9.7 | 10.3 | 1600 | 650 | 0.5 | 0.9 | 25/26.2 | 0.53/0.47 | 10100 | 634 | 24.97 |

| 012502 | 0.5 | 0.5 | 13.5 | 8.5 | 1600 | 650 | 0.63 | 0.95 | 34.3/21.6 | 0.24/0.65 | 6500 | 6280 | 18.68 |

| 09452 | 0.45 | 0.45 | 10 | 8.6 | 1600 | 650 | 0.45 | 0.88 | 25.4/21.8 | 0.55/0.71 | 15570 | 970 | 33.71 |

| 08603 | 0.5 | 0.6 | 9.4 | 9 | 1600 | 650 | 0.6 | 0.95 | 23.8/23.1 | 0.56/0.51 | 9000 | 560 | 24.38 |

| 08502 | 0.5 | 0.5 | 9.5 | 8.6 | 1600 | 650 | 0.89 | 0.47 | 24.13/21.8 | 0.50/0.65 | 10140 | 634 | 29.93 |

| 06803 | 0.7 | 0.8 | 7 | 5.5 | 1600 | 650 | 0.75 | 1.53 | 17.8/14 | 0.72/1.0 | 16000 | 1000 | 28.56 |

| Alkali resistance PA061002 |

1 | 1 | 4.5 | 5.5 | 1600 | 650 | 0.65 | 1.63 | 17/14 | 0.35/0.60 | 5920 | 370 | 14.85 |

| 09603 | 0.5 | 0.6 | 10.5 | 9.2 | 1600 | 650 | 0.65 | 1.05 | 26.67/23.4 | 0.45/0.48 | 8300 | 518 | 44.87 |

| 07803 | 0.8 | 0.8 | 8 | 8 | 1600 | 650 | 1.15 | 1.66 | 20.3/20.3 | 0.45/0.45 | 6400 | 400 | 16.26 |

| 07903 | 0.8 | 0.9 | 7.6 | 6.5 | 1600 | 650 | 1.25 | 1.76 | 19.3/16.5 | 0.51/0.63 | 9184 | 574 | 12.96 |