Paper Machine Clothing 2.5 Layer Forming Fabric

Description 2.5 layer forming fabrics are also known as support Shute double-layer fabrics or double-layer extra designs. It’s a double-layer design with an extra Shute yarn added on the forming side between the 2 regular cross-direction yarns. In order to furth……

Description

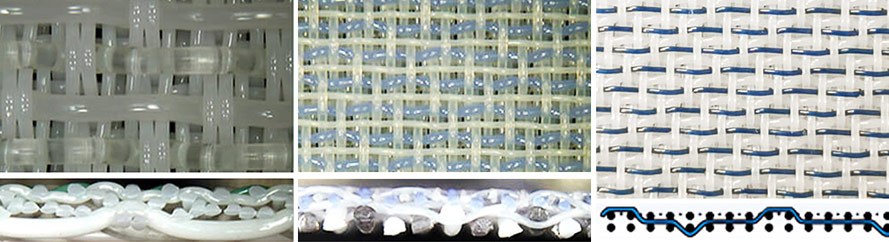

2.5 layer forming fabrics are also known as support Shute double-layer fabrics or double-layer extra designs.

It’s a double-layer design with an extra Shute yarn added on the forming side between the 2 regular cross-direction yarns.

In order to further improve the characteristics of the double-layer design forming fabric, we increased the weft density on the sheet side during the weaving process. The result is better sheet support that improves the wire mark, retention, and surface properties of the paper.

In addition, the number of wefts on the machine side is reduced, thereby increasing the three-dimensional space, thereby enhancing the drainage capacity.

16-shed 2.5 layer forming fabrics

Feature

● Double MD yarn lock on machine side which withstands high MD loads and resists CD ridging.

● Increased weft yarn diameter on machine side and long CD crimp provides better life time.

● Provides good sheet support and excellent drainage capability.

● Easy to release the sheets.

● Excellent fiber distribution.

● Superior abrasion resistance

Application

2.5-layer forming fabric is one of our best-selling products, suitable for the production of Printing paper, Wrapping paper, Board grade, Onion-skin paper, Newsprint, and so on. Paper machines with speeds of 200-500 m/min.

Specifications

| Model | Thread Diameter

(mm) |

Density

(No.s/cm) |

Air Permeability

(m³/m²h) |

||

| Warp | Weft (top/bottom) | Warp | Weft | ||

| 2B3316 | 0.28 | 0.20,0.27/0.40,0.40 | 37~38 | 40~41 | 6000 |

| 2B3316-1 | 0.28 | 0.20,0.27/0.45,0.45 | 37~38 | 37~38 | 6000 |

| 2B3316-2 | 0.28 | 0.20,0.27/0.45,0.45 | 37~38 | 31~32 | 8000 |

| 2B5008 | 0.17 | 0.13,0.18/0.32,0.32 | 55~56 | 48~49 | 6500 |

| 2B5216 | 0.17 | 0.17,0.22/0.27,0.27 | 57.5~58.5 | 50~51 | 5300 |

| 2B5216-1 | 0.17 | 0.19,0.22/0.35,0.35 | 57.5~58.5 | 43.5~44.5 | 6200 |

| 2B5408 | 0.17 | 0.13,0.20/0.35,0.35 | 59~60 | 43~44 | 6300 |

| 2B5416 | 0.17 | 0.13,0.20/0.35,0.35 | 59.5~60.5 | 42~43 | 6000 |

| 2B5608 | 0.17 | 0.13,0.18/0.22,0.22 | 61~62 | 52~53 | 5700 |

| 2B5608-1 | 0.17 | 0.13,0.20/0.25,0.25 | 60~61 | 54~55 | 5600 |

| 2B5608-2 | 0.17 | 0.13,0.20/0.32,0.32 | 60~61 | 48~49 | 6000 |

| 2B5608-3 | 0.17 | 0.13,0.20/0.35,0.35 | 60~61 | 47~48 | 5600 |

| 2B5608-4 | 0.17 | 0.13,0.20/0.32,0.32 | 61.5~62.5 | 55.5~56.5 | 6900 |

| 2B5608-5 | 0.18 | 0.13,0.18/0.22,0.22 | 62~63 | 53~54 | 6800 |

| 2B5608-6 | 0.18 | 0.13,0.20/0.25,0.25 | 61~62 | 61~62 | 5940 |

| 2B5608-7 | 0.15 | 0.13,0.18/0.25,0.25 | 62~63 | 53~54 | 6600 |

| 2B5608-8 | 0.15 | 0.13,0.18/0.32,0.32 | 61~62 | 56~57 | 6400 |

| 2B5608-9 | 0.17 | 0.13,0.18/0.35,0.35 | 61~62 | 51~52 | 6900 |

| 2B5608-10 | 0.17 | 0.13,0.22/0.35,0.35 | 61.5~62.5 | 48.5~49.5 | 5800 |

| 2B5808 | 0.17 | 0.13,0.18/0.22,0.22 | 63~64 | 53~54 | 6500 |

| 2B5808-1 | 0.17 | 0.13,0.20/0.25,0.25 | 63~64 | 54~55 | 5000 |

| 2B5808-2 | 0.17 | 0.13,0.20/0.25,0.25 | 63~64 | 51.5~52.5 | 5100 |

| 2B6208 | 0.17 | 0.13,0.18/0.20,0.20 | 68~69 | 56.5~57.5 | 5500 |

| 2B6208-1 | 0.17 | 0.13,0.18/0.20,0.20 | 68~69 | 54.5~55.5 | 6000 |

| 2B6208-2 | 0.17 | 0.13,0.18/0.23,0.23 | 63~64 | 51.5~52.5 | 5100 |

| 2B6216 | 0.17 | 0.13,0.18/0.23,0.23 | 68~69 | 61.5~62.5 | 5600 |

| 2B6216-1 | 0.17 | 0.13,0.20/0.25,0.25 | 68~69 | 64.5~65.5 | 6400 |

| 2B6216-2 | 0.17 | 0.13,0.18/0.25,0.25 | 68~69 | 51.5~52.5 | 5400 |

| 2B6216-3 | 0.17 | 0.13,0.20/0.35,0.35 | 68~69 | 52.5~53.5 | 5500 |

| 2B6216-4 | 0.17 | 0.13,0.20/0.35,0.35 | 68~69 | 49.5~50.5 | 8000 |

| 2B6216-5 | 0.17 | 0.13,0.20/0.35,0.35 | 68~69 | 46.5~47.5 | 7000 |

| 2B6408 | 0.17 | 0.12,0.18/0.20,0.20 | 70~71 | 57~58 | 6200 |

| 2B6408-1 | 0.17 | 0.12,0.18/0.20,0.20 | 70~71 | 65~66 | 6500 |