In today’s fast-paced industrial landscape, businesses need high-performance filtration solutions to meet ever-evolving demands. Polyester filter mesh stands out as a versatile, durable, and cost-effective option across a variety of sectors, including automotive, medical, and water purification industries. As the demand for reliable filtration systems increases, so too does the need to educate potential customers on why polyester filter mesh is an ideal choice.

In this article, we explore the features of polyester filter mesh, its various applications, and how to leverage these strengths to enhance your product’s sales potential.

What Makes Polyester Filter Mesh the Best Choice?

1. Superior Durability and Chemical Resistance Polyester filter mesh is known for its excellent resistance to a wide range of chemicals, including acids and alkalis. This makes it ideal for industrial settings where exposure to corrosive substances is common. Compared to other materials like nylon, polyester has a higher tensile strength, giving it enhanced durability in demanding conditions. Polyester can also withstand high temperatures without losing its structural integrity, an important feature for applications in the automotive and aerospace industries

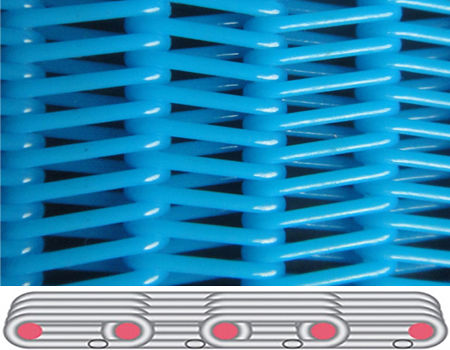

2. Wide Range of Mesh Sizes for Diverse Filtration Needs Polyester filter mesh comes in an extensive variety of mesh sizes, ranging from 25 microns to as fine as 2000 microns, enabling precise filtration capabilities. This flexibility allows it to be used for both liquid and air filtration, making it a go-to solution for industries requiring separation of particles in different media, such as water treatment facilities, food processing plants, and even air purification systems

3. Customizable and Easy to Install Whether you need polyester mesh in disc, tube, or belt form, manufacturers can tailor the product to meet specific operational needs. Polyester filter mesh is not only versatile in its forms but also easy to clean and maintain. This is a key selling point for industries such as medical filtration, where maintaining a sterile environment is critical

Industrial Applications of Polyester Filter Mesh

Understanding where polyester filter mesh fits in can help you target the right market segments. Let’s dive into some of its most common applications.

1. Water Filtration Polyester filter mesh is widely used in water filtration systems, particularly in the treatment of drinking water, industrial wastewater, and even in household filtration devices. Its hydrophobic properties allow for efficient separation of water from particles, making it ideal for clean water filtration

2. Automotive and Aerospace Sectors Polyester mesh’s resistance to heat, chemicals, and mechanical stress makes it a popular choice in the automotive and aerospace industries. It is used in air filters for engines, fuel filtration systems, and even in the construction of lightweight, durable panels

3. Medical and Pharmaceutical Filtration Polyester mesh is commonly used in the healthcare industry due to its strength and sterility. It can be applied in medical devices like IV bags, surgical drapes, and braces. Its ability to be treated with antimicrobial coatings enhances its value in sterile environments, helping prevent contamination and infection

4. Food and Beverage Industry In food processing plants, polyester filter mesh plays a crucial role in filtering liquids like oils, syrups, and even air in ventilation systems. Its FDA compliance and the ability to handle high volumes of material while maintaining precision make it a valuable asset for the food and beverage sector

How to Position Polyester Filter Mesh for Maximum Sales Impact

When marketing polyester filter mesh, your sales pitch should emphasize its adaptability across multiple industries and the cost-efficiency it brings due to its durability and ease of maintenance. Here are some key points to highlight:

1. Highlight Customization Customization is a major selling point. Polyester filter mesh can be tailored to suit specific filtration needs, from the mesh count and size to the form it takes—whether that’s filter discs, belts, or tubes. This adaptability makes it a perfect fit for a variety of applications and industries, and it’s an angle that can help you target niche markets with very specific needs

2. Stress Durability and Longevity In industrial settings, downtime due to equipment failure can be costly. Emphasize the longevity and robustness of polyester mesh as a long-term investment that minimizes the need for frequent replacements, saving companies both time and money in the long run

3. Showcase Versatility in Harsh Environments Polyester mesh’s resilience against heat, chemicals, and UV rays make it a top choice for industries that operate in harsh conditions. For example, in the automotive and aerospace industries, filters must withstand high temperatures and chemical exposure without degrading. Being able to meet these stringent conditions makes polyester mesh an attractive option for buyers in these sectors

4. Leverage Sustainability With sustainability becoming a critical factor for many buyers, polyester filter mesh’s recyclability can be a strong selling point. Polyester is an environmentally friendly option because it can be recycled and reused, fitting into the circular economy goals many industries are now striving to meet

Conclusion

Polyester filter mesh offers immense potential in terms of versatility, durability, and cost-effectiveness. By understanding its wide range of applications, from water filtration to aerospace, you can position your product as a reliable, high-performance solution for diverse industries. Focus on its customizable nature, chemical resistance, and long-lasting properties to appeal to a broader audience. By doing so, you’ll be able to drive sales, grow market share, and establish your brand as a leader in industrial filtration solutions.

Take advantage of this booming market by presenting polyester filter mesh as the go-to material for industries looking for top-tier filtration solutions.